From Urban Textile Waste to High-Value Circular Materials

The Textiles Symbiotic Flows pilot addresses one of the most complex and underperforming urban waste streams by transitioning from fragmented, manual textile sorting to an integrated, automated, and high-value circular processing system. The pilot focuses on transforming post-consumer textiles from an urban waste management burden into a reliable secondary raw material for industrial reuse.

The problem

Textile waste is one of the fastest-growing and most challenging waste streams in European cities. Urban textiles are highly heterogeneous, often composed of blended fibres, dyes, and chemical additives, and are typically collected with limited pre-sorting. As a result, the vast majority of post-consumer textiles are either downcycled, exported, incinerated, or landfilled.

Globally, less than 1% of materials used in clothing are recycled into new clothing. This is not due to a lack of textile waste, but to structural limitations in current recycling systems. Key bottlenecks include:

- Manual sorting processes: Existing textile sorting relies heavily on manual labour, which lacks the speed, consistency, and precision required to classify textiles by fibre composition, quality, and condition at scale.

- Material complexity and contamination: Mixed fibres, colour treatments, and chemical finishes inhibit effective recycling pathways, rendering many textile streams unsuitable for conventional mechanical recycling.

- Downcycling as the dominant outcome: When recycling does occur, it often degrades material quality, limiting outputs to low-value applications such as industrial wipes, rather than closing the loop back into high-performance products.

For cities, this results in increasing waste management pressure and the systematic loss of valuable material resources that could otherwise support local industrial value chains.

What THESEUS is doing

THESEUS is implementing a holistic “collection-to-product” value chain that integrates automated sorting with advanced chemical recycling and fibre production technologies.

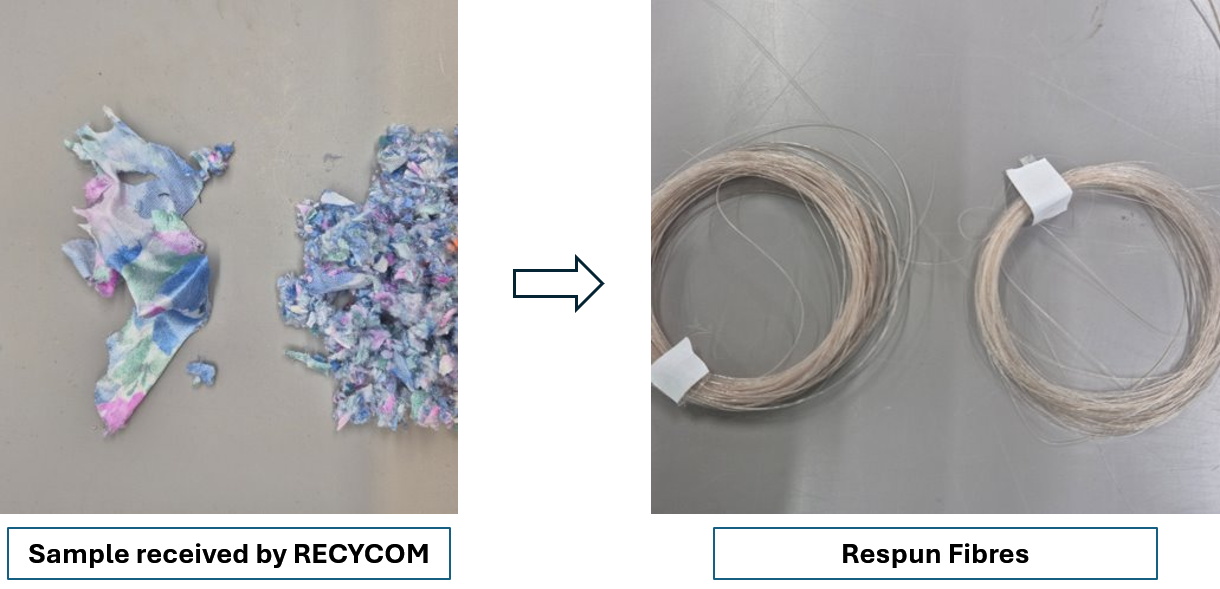

- Sourcing: Post-consumer textiles are collected through dedicated urban collection systems, the community “purple bins” managed by RECYCOM. These systems enable separation from mixed municipal waste streams and ensure a stable and traceable supply of textile feedstock.

- Automated sorting: Advanced optical monitoring systems combining RGB and hyperspectral imaging scan incoming textile items. Deep learning algorithms analyse the data to classify garments by fibre type (thermoplastic, natural, mixed) and colour. Compressed air nozzles are then activated to blow the garment to the bin that corresponds to its category.

- Advanced processing:

- Glycolysis: PET-based textiles are processed using a microwave-assisted glycolysis reactor with ionic liquids, enabling depolymerisation into reusable monomers.

- Spinning and encapsulation: Recovered materials undergo melt spinning for thermoplastics or solvent and wet spinning for natural fibres. During fibre formation, active compounds such as antimicrobial agents or water and oil repellents are encapsulated within the fibres, producing functionalised circular materials.

This pilot goes beyond conventional textile recycling by integrating advanced automation, human-in-the-loop control, and high-value upcycling into a single operational system.

- Human-Robot collaboration: Unlike standard automated lines, this pilot introduces an XR application that provides clear visual information to a human operator to facilitate the sorting process and allows them to interact with the robotic sorting system.

- Upcycling vs. Downcycling: Rather than degrading the material, the project aims to create novel circular high-value products. By using linker chemistry and plasma treatment to attach active compounds (e.g., polydimethylsiloxane), the project turns waste into enhanced fibers suitable for technical applications, not just rags or stuffing.

- Efficiency: The automated line aims for a sorting accuracy exceeding 90% and is estimated to increase capacity by roughly 30% compared to previous manual processing.

Expected outcomes and impact

The immediate goal is to demonstrate these technologies at a semi-industrial scale to validate their technical and economic feasibility.

- Capacity expansion: The automated sorting line is designed to substantially increase textile sorting capacity compared to current manual processes, enabling the handling of thousands of tonnes per year and supporting higher recovery rates and material quality.

- New product creation: The recycled fibers will be tested by end-users to manufacture concrete prototypes, including mattress felts, insulation, and building materials incorporating recycled textile content.

- Strategic shift: Long-term, these innovations aim to support a completely new value chain for the valorisation of textile waste within Greece, covering needs and addressing challenges of the local industry.

All in all, the Textiles Symbiotic Flows pilot demonstrates how advanced automation, human–robot collaboration, and chemical upcycling can convert post-consumer textiles into high-quality secondary raw materials at scale. By addressing the structural bottlenecks of manual sorting and low-value recycling, THESEUS establishes a viable pathway from urban textile waste to functional industrial products. The pilot provides a replicable model for cities seeking to reduce landfill dependency, strengthen local circular value chains, and transition textile waste management from a cost burden into a strategic resource